Downloads

Spotlight on PFPE technology providing specialized functional performance at minimized thickness for advanced coatings in aerospace and automotive

SÃO PAULO, Brazil, October 13, 2015 –At ABRAFATI 2015, Solvay Specialty Polymers will be presenting its extensive range of high-performance perfluoropolyether (PFPE) fluids for demanding functional coatings in aerospace and automotive industry. The spotlight on Solvay’s booth D/7/E will be on Fluorolink® PFPE materials that lend specialized functions to products such as anti-ice, easy-to-clean coatings without significant increase of wall thickness, helping to meet advanced targets of efficiency, productivity and sustainability.

“ABRAFATI is the most important event in the Latin American coatings sector, whose annual sales is almost 10 billion dollars, driven by a significant growth potential particularly for functional coatings,” says Milan Krumbe, global market director coatings for Solvay Specialty Polymers. “We are determined to help coating formulators in this dynamic industry with our expertise and advanced PFPE technology in particular, to stay ahead of market requirements and gain a competitive edge.”

Krumbe goes on to say: at Solvay, the development of functional fluids for coatings is part of an overall approach to enhancing the durability and sustainability of applications while at the same time reducing customers’ total cost of ownership. Essentially, functional coatings are products providing additional properties to a substrate beyond classical surface protection or decoration. This added value can not only have a major impact on enhancing the performance and safety of technical goods, but will in most cases also help to consolidate manufacturing steps, reduce power consumption and speed the time-to-market.

At the forefront of Solvay’s polymer technology for functional coatings, Fluorolink® PFPE fluids are an ideal fit as surface treatment or polymer modifiers for improved and/or added-value properties. They reduce the surface energy of coatings and can deliver exceptional oil and stain repellency as well as self-lubricity. Examples are easy-to-clean and self-healing coatings. At ABRAFATI, the company will feature advanced Fluorolink® solutions for important application areas: anti-ice coatings for aerospace with superior hydrophobic performance; aesthetic long-term automotive coatings with easy-to-clean, oleophobic and anti-fingerprint properties, where the use of PFPE as a low-content modifier, results in a significant reduction of surface energy.

“While the superior and durable effect of Solvay’s hydrophobic PFPE technology can be considered a major breakthrough, we are also actively investigating further in tailor-made functional solutions with extremely high abrasion resistant qualities, which are adapted to the coating matrix and application process requirements,” concludes Milan Krumbe.

As bi-functional perfluoropolyethers, Fluorolink® surface treatment and polymer modifiers combine the unique high-performance properties of fluorinated materials with the high versatility of reactive end groups to facilitate interaction with substrates and other polymers. This adaptable chemistry makes them highly suitable as functional additives in polyurethane, polyester, acrylic and epoxy coatings requiring any one, or combinations of, special properties such as low coefficient of friction, enhanced chemical resistance, water, oil, soil and stain repellency, anti-fouling and easy cleanability, anti-stick or anti-graffiti performance.

Most of these benefits can be obtained at low contents without changing the bulk properties of the host material. Higher amounts can be used to enhance mechanical properties such as hardness, minimize gas permeability or lower the refractive index of coatings. Specific grades include Fluorolink® P56 for waterborne systems, AD1700 and MD700 for UV-curable coatings, and E10-H for polyurethane, polyester or epoxy coatings. Fluorolink® S10 features ethoxy silane terminal groups capable of forming chemical bonds with ceramic, glass or other siliceous surfaces for greatly enhanced water and oil repellency. As water-based low/zero-VOC dispersion systems, all Fluorolink® PFPE products are manufactured without any PFOA, PFOS or C8 telomers.

During the three-day ABRAFATI 2015 event (October 13-15) at the Transamerica Expo Center in São Paulo, Solvay’s coatings experts will be available on Booth D/7/E to discuss market trends and how the company’s versatile specialty polymer technology offers innovative and cost-efficient, as well as sustainable coating solutions.

® Registered trademarks of Solvay

About Solvay Specialty Polymers

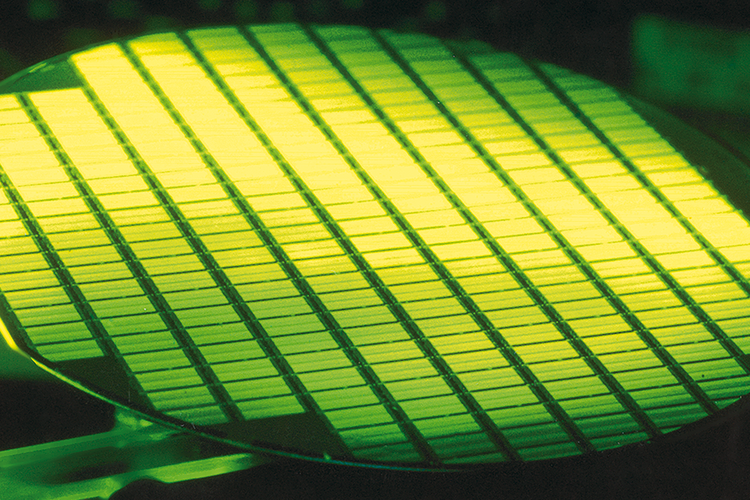

Solvay Specialty Polymers manufactures over 1500 products across 35 brands of high-performance polymers – fluoropolymers, fluoroelastomers, fluorinated fluids, semi-aromatic polyamides, sulfone polymers, aromatic ultra-high performance polymers, high-barrier polymers and cross-linked high-performance compounds – for use in Aerospace, Alternative Energy, Automotive, Healthcare, Membranes, Oil and Gas, Packaging, Plumbing, Semiconductors, Wire and Cable, and other industries. Learn more at www.solvayspecialtypolymers.com.

As an international chemical group, SOLVAY assists industries in finding and implementing ever more responsible and value-creating solutions. Solvay generates 90% of its net sales in activities where it is among the world's top three players. It serves many markets, varying from energy and the environment to automotive and aeronautics or electricity and electronics, with one goal: to raise the performance of its clients and improve society's quality of life. The group is headquartered in Brussels, employs about 26,000 people in 52 countries and generated 10.2 billion euros in net sales in 2014. Solvay SA (SOLB.BE) is listed on EURONEXT Brussels and EURONEXT Paris (Bloomberg: SOLB:BB - Reuters: SOLB.BR).