Download the files

Solvay’s new KetaSpire® PEEK XT takes performance to a new level

Bollate, ITALY, October. 16, 2019 --- Solvay introduces KetaSpire® PEEK XT, the industry’s first true high-temperature PEEK, at K 2019. This innovative material offers the chemical resistance of standard PEEK plus significantly higher strength and stiffness at elevated temperatures.

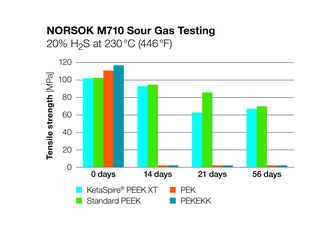

Solvay’s KetaSpire® polyetheretherketone (PEEK) XT delivers the exceptional chemical resistance of PEEK along with a 20°C (36°F) higher glass transition temperature and a 45°C (81°F) higher melting temperature than standard PEEK. Although other high-temperature polyketones exhibit thermal properties on par with KetaSpire® PEEK XT, their chemical resistance is significantly inferior to PEEK and KetaSpire® PEEK XT.

“We were able to boost thermal and mechanical performance while maintaining PEEK’s ether-to-ketone ratio, which accounts for the polymer’s superior chemical resistance,” said Doug Brademeyer, ultra-polymers business manager for Solvay’s Specialty Polymers global business unit.

A true PEEK polymer has a 2:1 ether-to-ketone ratio. All other high-temperature polyketones, which include polyetherketone (PEK), polyetherketone ketone (PEKK), and polyetherketone etherketone ketone (PEKEKK), alter this ratio and therefore are not true PEEK polymers.

Solvay’s new KetaSpire® PEEK XT polymer has a glass transition temperature of 170°C (338°F) and processes like standard PEEK at a 20°C (36°F) higher melt temperature. The material exhibits significantly higher strength and stiffness at elevated temperatures versus standard PEEK, with a 400 percent higher tensile modulus and nearly 50 percent higher tensile strength at 160°C (320°F).

In addition, KetaSpire® PEEK XT shows an extraordinary improvement in electrical properties at 250°C (482°F) vs. standard PEEK, increasing dielectric strength by 50 percent and volume resistivity by an order of magnitude.

KetaSpire® PEEK XT is available globally in neat, 30 percent glass fiber, and 30 percent carbon fiber reinforced injection molding and extrusion grades, as well as in fine powder form for compression molding and as coarse powder for compounding. All resins exhibit superior processing, melt stability and high-temperature chemical resistance compared to PEK, PEKEKK and PEKK. Industries of interest for this new material include oil & gas, electrical/electronics, wire coatings, and automotive.

To learn more about KetaSpire® PEEK XT visit Solvay’s booth C61 Hall 6 on Friday Oct. 18 at 14:30 for a thirty-minute live presentation.

For regular updates on Solvay Group’s activities at K 2019 please visit the online hub.

Solvay is an advanced materials and specialty chemicals company, committed to developing chemistry that addresses key societal challenges. Solvay innovates and partners with customers worldwide in many diverse end markets. Its products are used in planes, cars, batteries, smart and medical devices, as well as in mineral and oil and gas extraction, enhancing efficiency and sustainability. Its lightweighting materials promote cleaner mobility, its formulations optimize the use of resources and its performance chemicals improve air and water quality. Solvay is headquartered in Brussels with around 24,500 employees in 61 countries. Net sales were €10.3 billion in 2018, with 90% from activities where Solvay ranks among the world's top 3 leaders, resulting in an EBITDA margin of 22%. Solvay SA (SOLB.BE) is listed on Euronext Brussels and Paris Bloomberg: SOLB.BB - Reuters: SOLB.BR), and in the United States its shares (SOLVY) are traded through a level-1 ADR program. Financial figures take into account the planned divestment of Polyamides.

Solvay Specialty Polymers manufactures over 1500 products across 35 brands of high-performance polymers – fluoropolymers, fluoroelastomers, fluorinated fluids, semi-aromatic polyamides, sulfone polymers, ultra-high performance aromatic polymers, and high‑barrier polymers – for use in Aerospace, Alternative Energy, Automotive, Healthcare, Membranes, Oil & Gas, Packaging, Plumbing, Semiconductors, Wire & Cable, and other industries. Learn more at www.solvayspecialtypolymers.com.